Products

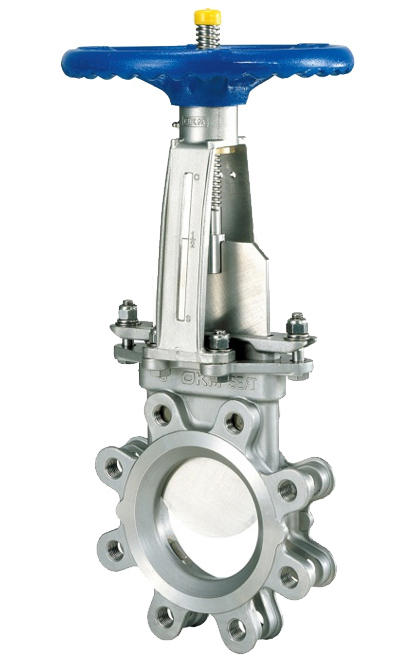

336J / 336Y

Knife Gate Valve

Applications

Paper-making, petrochemicals, chemicals, foods, mining, sewage treatment, high-concentration or high-viscosity fluids, etc.Actuators

Handle, cylinder, electric motor

336J

○ Max. service pressure:

1.0MPa(50 A to 300 A)

0.5MPa(350 A to 600 A)

○ Piping flanges: JIS 10K, JIS 5K

○ Production size: 50 A to 600 A

○ Max. service pressure:

1.0MPa(50 A to 300 A)

0.5MPa(350 A to 600 A)

○ Piping flanges: JIS 10K, JIS 5K

○ Production size: 50 A to 600 A

336Y

○ Max. service pressure: 1.0Mpa

○ Piping flanges: JIS 10K, JIS 5K

○ Production size: 350 A to 600 A

○ Max. service pressure: 1.0Mpa

○ Piping flanges: JIS 10K, JIS 5K

○ Production size: 350 A to 600 A

Catalog

Catalog